High-level bridge works specialist Spencer Group has delivered a complex £10m project to maintain the structural integrity of the Forth Road Bridge.

It follows the discovery in December 2015 that one of the eight links, which connect the bridge deck to the tower, had fractured, causing the bridge to be closed completely for more than three weeks while urgent repairs were carried out.

Spencer Group project manager Robbie Ryan views the bridge

A temporary splint was applied to the fractured link, followed by a permanent structural repair to that area. Bridge owner Transport Scotland then decided to replace the other seven links. Following a tender process, it selected Spencer Group for the works.

The £10m scheme has involved cutting out the truss end links and replacing them with what the firm described as a unique new sliding bearing system. To do this, a series of complex works had to be delivered to a part of the bridge that has limited accessibility and was not designed with replacement in mind.

Spencer Group installed temporary stairs and platforms below the bridge deck, allowing access to each bearing arrangement. Its team had to work in confined spaces within the main towers, manoeuvring large components to precise tolerances.

The replacement bearings were delivered to the bridge from a workboat, meaning that the works had to be co-ordinated with tide times within the busy Forth estuary.

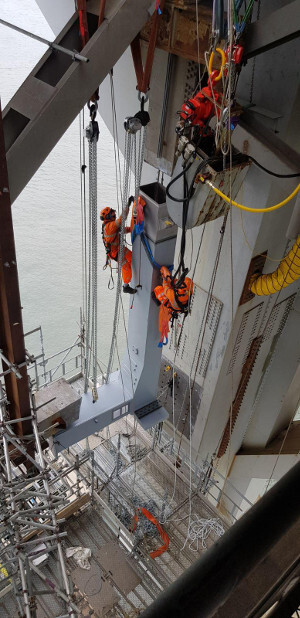

The project involved a series of complex works to a part of the bridge with limited accessibility

Despite these challenges, Spencer Group said the works had minimal impact on normal bridge operations, with road traffic flowing throughout.

Managing director Gary Thornton of Spencer Group said: ‘We're delighted to have completed this important project to maintain the structural integrity of the Forth Road Bridge and to add it to our extensive track record over many years of delivering critical, high-level works on landmark crossings.

‘The project showcased the expertise we bring to works such as this, which pose a range of major challenges.'

Projects manager James Barnes said: ‘This project has been particularly challenging in relation to access because the truss end links and the new bearings we have fitted are below the bridge deck, about 40 metres above the water.

‘With our supply chain we have fabricated over 200 tonnes of new steel and joined it to the existing structure in some very inaccessible areas.'

‘The pieces that we cut out to replace were 7-8 tonnes in weight and some of the heaviest lifts have been up to 16 tonnes.

'All the pieces have had to be lifted onto the bridge deck or lowered to the workboat, so there have been major lifting, hoisting and access challenges that had to be overcome.'

He added: ‘A key factor in the success of this project has been the collaborative approach between everyone involved.

'It's been a real team effort to come up with the right solutions and undertake the works in the most efficient manner, with safety the number one priority.

‘Long span bridges have a very long design life, meaning the quality of the work produced must be to the highest standard.'

Spencer Group said it has also introduced modifications that will make future works easier, including new permanent access stairs and platforms to allow easy and safe inspection and maintenance all year round.

Amey, the long-term maintenance contractor for the bridge represented Transport Scotland on the project.

A component is lowered into place below the bridge deck