This article is part of a series on the work of the CERCOM project (Circular Economy in Road COnstruction and Maintenance), which is funded by CEDR (Conference of European Directors of Roads) following its transnational research call of 2020.

CERCOM’s objective is to explore the barriers and opportunities of embedding the circular economy and resource efficiency into their member organisations and it is funded by Denmark, Ireland, the Netherlands, Norway, Sweden, Switzerland and the UK. The project is led by Research Driven Solutions in Ireland with partners from ITEN and Hello My PA (UK), Technical University of Delft (Netherlands) and the Danish Technological Institute (Denmark).

In a recent issue of Highways (October 2022), CERCOM defined resource efficiency (RE) and circular economy (CE) in the context of road construction and maintenance and presented a process diagram showing how this could operate in practice. In this article, the team presents how six National Road Administrations (NRAs) are implementing these concepts, and presents a framework through which highway authorities can assess their maturity for implementing RE and CE principles and give outline recommendations.

Through our investigations, we identified the following areas characterising the maturity with which RE and CE are being implemented by road administrations:

- CE Ambition: Many NRAs have goals focused on different aspects of sustainability and often these overlap with concepts of circularity. However, RE and CE are not, in general, being specifically targeted, despite the overarching nature of these objectives.

- Embedding CE: Some NRAs are adopting a more RE approach during highway maintenance and in designing maintenance regimes. Examples are a greater emphasis on achieving long service lifetimes, reducing waste and reducing embedded carbon.

- Performance monitoring (KPIs): As yet, there is little quantification of resource flows associated with highway maintenance and a lack of transparency between NRAs and the supply chain of the degree of RE achieved.

- Standards: development of standards is occurring but the limited scope and slow rate of modification remain barriers to innovation.

- Supply Chain: Some NRAs have engaged proactively with their supply chain to identify more RE options on construction projects. Early engagement, from design phase, resulted in novel options being considered.

- Business models: Most NRAs operate with primarily linear business models where price remains king. However, wider environmental performance, particularly in reducing carbon, is beginning to have an impact.

- Circular procurement: Some NRAs are starting to include CE and RE in their procurement processes. Good practice exists in the form of circular procurement guidelines and the use of environmental impact criteria to balance cost with environmental impact.

Some specific areas of good practice, being undertaken by National Highways and Rijkswaterstaat (Netherlands) are as follows:

Defining CE to meet national requirements and align with organisational objectives, leading to supporting objectives of:

- minimising demand for primary resources and maximising the reuse of resources already in use on the network in as high a value application as possible;

- working with suppliers to find new ways to deliver a more resilient and adaptable network;

- achieving security of supply through collaborative working with stakeholders, enabling investment in innovative approaches, securing long-term partnerships;

- looking to achieve net biodiversity gains;

- undertaking trials, feasibility studies, lessons learnt and knowledge transfer through ‘Pathfinder’ projects to support project level CE thinking

- starting with the end in mind to embed ‘end of life’ options at bidding stage of schemes e.g. requiring tenderers to include proposals for use/reuse of materials at end of first life and designing the tender evaluation criteria to value these options; or establishing long-term contracts with the supplier to ensure high-value reuse of resources.

Framework for assessing maturity

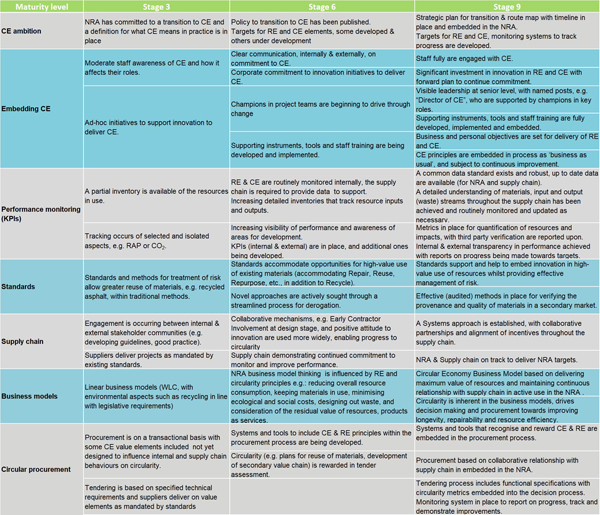

Building on the headings above, we developed a framework for assessing the maturity of circular thinking in road authorities.

The full framework consists of a rubric with nine stages of development in each of the seven categories, through which an authority would be expected to progress in its journey towards circularity.

Stages one to three represent an authority that is engaging in transition, followed by stages four to six, representing early stages of practising RE and CE, and stages seven to nine, representing active deployment.

Figure 1 shows an extract of three stages of the framework. The full framework is available on the project website and can be used by road authorities, following the guidance provided, for self-assessment.

Figure 1 Extract of part of Maturity Model

Recommendations

The work undertaken has led to the following recommendations for road authorities, which will be expanded as the project progresses and as knowledge transfer activities are developed:

- Define CE and RE in an organisational context – and set associated objectives and targets.

- Assess the current organisational maturity using the simple rubric developed in this project or more comprehensive options with third party verification – this will enable areas of strengths and priorities for development to be identified.

- Communicate CE and RE ambition throughout the organisations and appoint champions – the ambition is for CE and RE to be integrated as business as normal in organisations.

- Enter into long-term agreements with contractors, considering end of first life at outset – to give contractors the business case to invest in sustainable solutions.

- Undertake trials and ‘pathfinder’ projects with the acceptance that they will not be perfect – share lessons learned to build on in future schemes.

- Share data with contractors to improve resource use – improve the transparency in resource use, seek to innovate to improve CE and RE and monitor progress.

- Develop performance-based standards and specifications – increased resource efficiency, while achieving a consistent level of performance implies doing things differently. Standards based on performance allow innovation and increased material re-use.

- Consider business models that account for overall value – current business models are often based on lowest initial capital cost, and don’t consider potential future maintenance interventions and end-of-life costs.

A report giving further details of the topics discussed above is available in the resources section of the CERCOM website. In future issues of Highways magazine, more information on the project activities will be provided, including how an innovative risk-based framework and lifecycle analysis will help NRAs to make decisions around how to assess risk and base business models on factors other than capital cost.

For more information, or to get involved in the project, visit the CERCOM website.