A water technology firm has said an innovative sustainable drainage material could be installed on hundreds of roadside outfalls across the country after it was used to protect a stream polluted with toxic metals.

Metals known to be directly toxic to fish and insects in rivers and streams are released through the abrasion of vehicle tyres and brake pads and dissolve in surface water during heavy rain.

The Environment Agency has identified more than a hundred water bodies in England that are currently polluted with either copper or zinc, and some with both.

The new granular treatment media developed by SDS turns roadside filter drains into treatment devices that protect the water environment from dissolved copper and zinc pollution.

It was installed into an existing filter drain along a 1km stretch of the M56 that discharges into Mag Brook, a small stream that runs through farmland to the south of Lymm in Cheshire. Water from the brook flows via another stream, Bradley Brook, into to a small lake known as Lymm Dam (pictured), a popular local beauty spot and nature reserve.

SDS said it could now be installed into many hundreds of kilometres of existing filter drains that flank motorways and trunk roads across the country and are close to areas known to be at risk of metals pollution from runoff.

It said Highways England has identified 2,500 high-risk pollution locations as part of its ongoing Priority Outfall Programme and has been looking for practical and affordable treatment solutions.

Jo Bradley, a water quality specialist at SDS Limited who was closely involved in developing and testing the new material, said: ‘Highway runoff remains one of the greatest pollution threats to our rivers and streams, and a significant proportion of the 2,500 priority outfalls in England remain difficult to solve using conventional solutions because of the limitations of space or cost. Yet, often these pollution threats from the heaviest traffic areas are in rural, or semi-rural locations with sensitive ecosystems like Mag Brook.

‘The risk assessment revealed the stream was vulnerable to pollution because of the high traffic volumes travelling to and from Manchester and the airport. There was very little water flow in the brook to dilute the runoff from the motorway. It confirmed a treatment scheme was needed to clean the water, reducing both the soluble copper and zinc levels to bring them within permitted levels.

‘There was no space to build SuDS ponds or other vegetative features behind the carriageway to treat the metals, or to install a manufactured stormwater filter to capture the pollutants. So, it would have been extremely problematic to mitigate the pollution risk otherwise.

‘This new treatment media offered the prospect of treating the pollution simply by adding it into the existing filter drains. It would have been extremely problematic to solve the pollution risk at Mag Brook otherwise.’

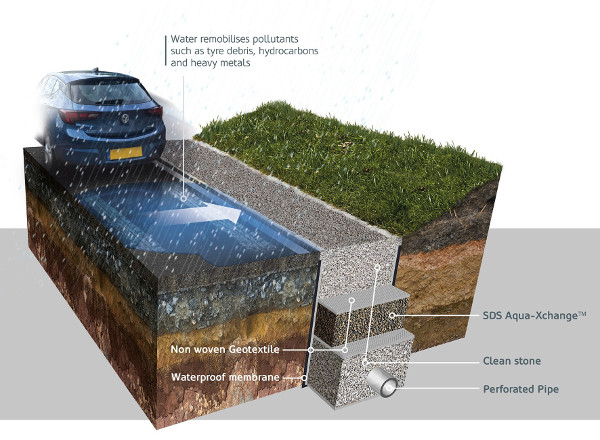

Filter drains are stone-filled trenches that capture suspended solids as they run off the sides of the carriageway. Silts and sediment in the runoff are collected in the spaces between specially-graded stone before the water enters a perforated pipe at the bottom of the trench. However, conventional filter drains are not capable of capturing soluble pollutants.

SDS said that when added to the filter drain, a layer of ‘Aqua-Xchange’ uses the processes of adsorption and ionic exchange to capture the metals dissolved in the runoff as they filter through the material. The chemical process forms unbreakable bonds, so the pollutants are retained even in heavy storms and during winter gritting.

It added that the product has been developed and manufactured from a unique combination of naturally-occurring materials and proven in laboratory testing to achieve 99% removal of dissolved copper and zinc.

SDS said this was ‘more than adequate’ to tackle the levels of pollution identified in the risk assessment for Mag Brook.

Contractors BDB Special Projects Ltd were appointed to complete the installation. Ben Dobson, Director of BDB said: ‘The whole project was extremely straightforward, and not significantly different to a conventional filter drain refurbishment. We were able to complete the works during ten overnight closures, with minimal disruption to the travelling public.’

As there were cabled services in the existing filter drain, a vacuum excavator was used to remove the existing stone to the desired 400mm depth.

A team followed directly behind to line the trench with a geotextile membrane, then a grab wagon was used to discharge each cubic metre bag of the new material into the trench and it was raked level.

The 250mm layer was covered with a geosynthetic grid for surface stabilisation, then with a final layer of clean stone. Surface water percolates through the non-woven geotextile wrap and filters through a further layer of stone before entering the perforated pipe at the bottom of the trench.

SDS said further installations of Aqua-Xchange are already in the design stages for locations across the UK.