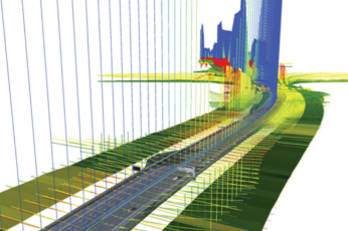

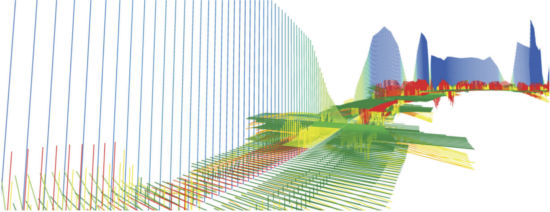

Jon Masters provides an in-depth analysis of Highways England’s latest work in computer-led design and its potential to change the way we deliver the next genera-tion of roads.

Engineers employed in the design stages of Highways England’s smart motorway programme are getting to grips with a new way of working – collectively labelled Rapid Engineering Model (REM) - first reported in Highways December 2018.

The main aim is to achieve greater efficiency in the design of smart motorway schemes. This should be feasible, given that every project in the programme is essentially doing the same thing: creating eight running lanes in the space where there are usually six plus two hard shoulders.

Each smart motorway scheme is different in detail, but there is scope for automating repetitious elements of the designs.

‘Our goal for the next 12 months, is to get to the point where outline designs can be completed where 80% of the effort is automated, including schedules for cost and project programme,’ says Lorraine Butler, Highways England’s delivery director for operations, business improvement and change in the smart motorway programme .

Highways England is nearing this stage of automation after testing REM methods against conventional manual means of drawing up outline designs. REM is not best described as a system of software, Ms Butler says, but as a ‘workflow system’, incorporating a number of design and management tools that most engineers working for Highways England are familiar with.

‘REM utilises a lot of what we’ve already got. It is compatible and interoperable with our existing software, such as Oracle’s Primavera P6 management software, building information modelling, geographic information systems and other information systems,’ she says.

The basis for REM is a ‘rules-based platform’ – which is essentially all of the rules and regulations of the Design Manual for Roads and Bridges and Interim Advice Note 161 for smart motorways, but in a digitalised format.

On top of this platform, or attached to it, is a library of standardised components including barriers, gantries and all of the roadside equipment needed for smart motorways, their Emergency Areas (EAs) and traffic monitoring.

‘The REM system gives us the ability to take the digitalised rules base and the components catalogue and bring these together, to see how the design works overall,’ Ms Butler says.

‘The output is the design visualised in three dimensions, with the technical specification of each item behind. The system gives all of the data and drawings needed to ensure it all fits and for contractors to use for further value engineering.’ REM is a work in progress and does not yet replace conventional manual methods of outline design. Some important capabilities of the new system have now been proven, however.

‘We tested REM to see if it would produce the same design as manual methods, and it did. This gave us assurance and confidence in the system. We tested some different things, such as driver visibility in relation to sign gantries. If this is wrong or insufficient, can REM diagnose and fix it? Yes it can. It is self-diagnosing and can solve problems,’ Ms Butler says.

The system is also developing incrementally and becoming more sophisticated. Jacobs engineer Liam Gallagher is seconded to Highways England as its project manager for REM. He says: ‘We started the journey of applying REM by using it to assess and prove initial operational concepts of smart motorway schemes. It has now developed to help with providing assurance of pieces of outline design work.

‘It has become useful for rapidly re-running designs, of positioning of EAs for example, if a change is needed. REM is now an important part of consultations and technical meetings, allowing projects to be demonstrated in a digital format.’

Further capabilities are being built in, as more layers of data are added, including 3D topographical information and environmental rules. The system has been designed to flag up the risk of problems with the positioning of components to a red, amber, green rating, to show where more human input is needed to solve problems.

‘As we are adding more data, we’re effectively giving REM additional layers of intelligence,’ says Ms Butler.

‘The system is now smart enough to alert the user if human intervention is needed to solve a problem.’

An example, she says, could arise from the positioning of a gantry on a steep gradient, requiring larger foundations.

‘It may be that the best, most economical solution, would require two gantries instead of one, or that a more unusual or innovative form of support is needed. The important thing to note is that REM will alert users where a problem needs human help,’ Ms Butler says.

She also points out that while the system stops certain rules from being broken, it does not prevent changes within those parameters. For instance, distances between EAs cannot exceed the maximum allowed, but REM does not prevent designers from closing up the spacing if appropriate.

Inevitably, the advent of further automation raises questions of whether jobs and livelihoods are being gradually cut out of the process, but Ms Butler has a good answer to that: ‘We will always need an element of human skill and ingenuity. We are now arriving at a stage where computer-aided design is being overtaken by human-aided computer design, where machines can be left to do more of the routine leg work, allowing skilled people more time to do the thinking and detailed design that adds value. ‘REM represents a new way of working that will allow better use of resources. As we go on, as REM software is used for outline design, we will be able to focus human efforts on refining the designs, being innovative and extracting greater value.’

Mr Gallagher says: ‘REM was initially all about proving operational concepts, which we have managed to lower from a nine-month process down to four or five weeks. Next will come the reduction of the time needed for base level design, from weeks to a matter of days.

‘Essentially, we will be automating design of civil engineering in verges and central reserves, which is where the majority of the smart motorway work is, with 80% of the manual design effort put into the crucial part of refining the designs.’

There is more to be done in partnership with Highways England’s smart motorway supply chain before that point is reached. At present, Ms Butler’s team is working on adding more layers of data to the REM system. A process of engaging with suppliers is under way to build up the digitalised component library, while REM as it stands is being used as a means of checking designs.

‘We are putting the system through more testing as we add more data layers, running it parallel to conventional designs and using it to visualise digital rehearsals on how projects will be built,’ she says.

‘We want increased standardisation of designs and certainty of delivery cost, as well as greater efficiency. By the end of this year, we should have that from using REM. The intention is to then use the system for base level design of all smart motorway schemes of the second Road Investment Strategy.’

Pictures of the software from Highways England.